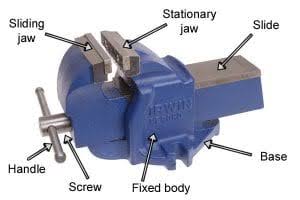

An engineer’s vise, also known as a metalworking vise, machinist’s vise, or, informally, a “bench vise”, is used to clamp metal instead of wood. It is used to hold metal when filing or cutting. It is sometimes made of cast steel or malleable cast iron, but most are made of cast iron.

BENCH VICE PARTS

- The Base The base of the vise is the part that holds everything together. It is truly the life of the party. The base of the vise is fastened to the bench and it comes in different designs. Some can be clamped in place; the others can be bolted. There are also swivel and vacuum bases available for different purposes.

2. The Jaw

This is where everything stays. The jaw is jaw-like and clamps everything in place. It comes in two different parts. Considering the nature of the job, the jaws can take the form of wood, plastic, or metal.

The sliding jaw: this part of the jaw moves when the handle is turned. It also applies pressure on the object being clamped. If you are new to clamping, it’s pretty easy to spot out which part of the clamp is the sliding jaw, since it’s the part that allows motions and has a handle sticking through.

3. The Slide

This part moves when the handle is turned, applying pressure to the object. It is attached to the sliding jaw.

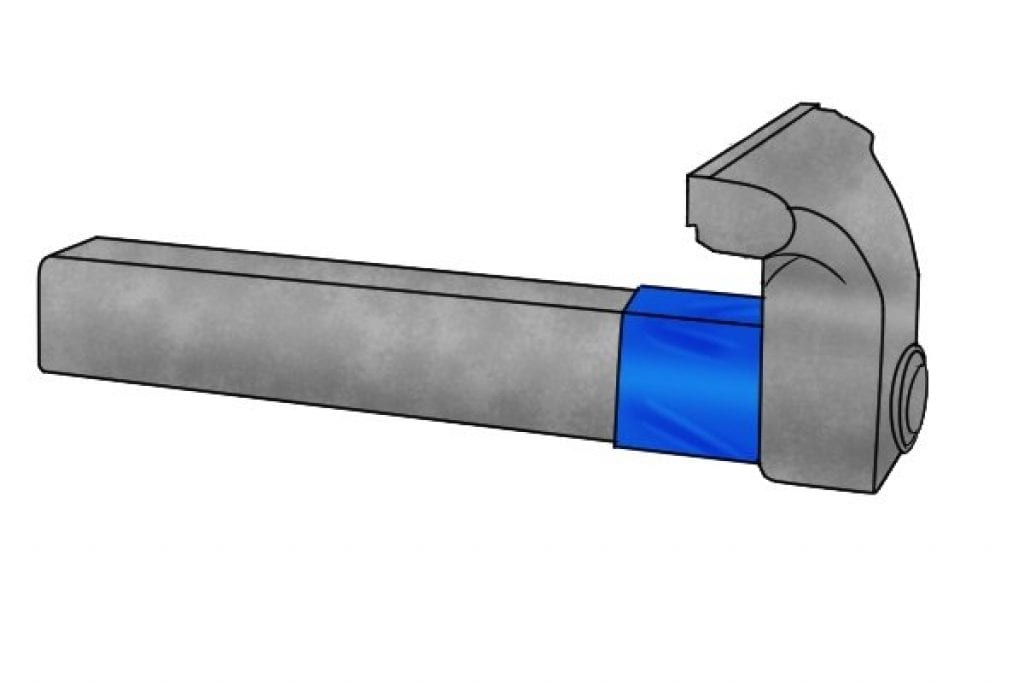

4. Main Screw

This is where the magic happens. The force applied to the handle is transformed into the movement of the sliding jaw, which moves towards the static jaw. This jaw is conspicuously attached to the handle—and extends through the vise. The main screw is an essential part. It is so vital that if the main screw is not manufactured or comes with flaws creating weaknesses, the vise will not hold well at all. You might be able to apply the pressure but don’t count on it being maintained.

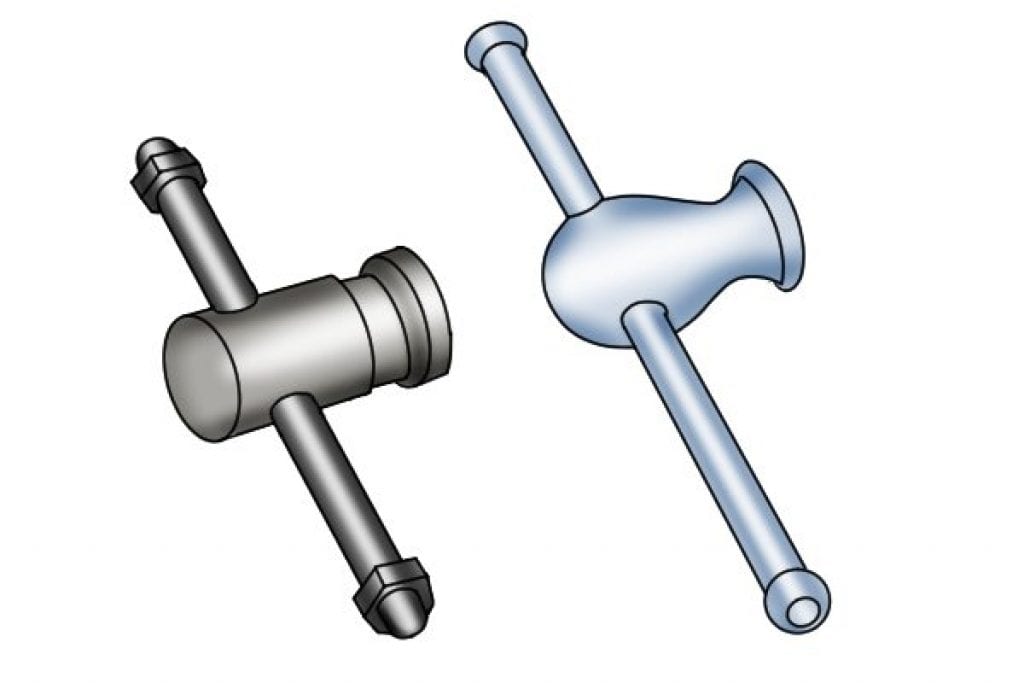

5. Handle The handle is the most sophisticated part of the vise. With the principle of leverage, you can easily convert a minimal force to something unstoppable. The handle has a lever attached to it. The operation of the handle is a perfect scene of The sight is something that will blow the mind of anyone, especially those with less engineering skill. Applying too much force on the handle can be tempting. But if done out of proportion, it can lead to explosive results. The power applied to move the handle multiplies and gets accompanied by the actions of the main screw. While clamping, if any material observes a bend, it’s best to stop and reverse the handle to release the pressure level.

6. The Anvil This can come in handy form when light-shaping of materials. It can also be used as a base to your hammer nails, although this feature is only found in metal vises.

YOUTUBE VIDEO LINKhttps://youtu.be/yDmVwsWrxUI

MCQ LINK https://docs.google.com/forms/d/e/1FAIpQLSdellR2KR9fOJw0nECR0GkK87EppjodBJnDH4A97Z7srX5_2A/viewform?usp=sf_link

REFERENCE VIDEO https://youtu.be/KgaQVyXfaUE