The lathe machine operations are classified into three main categories and are as follows Following are the Lathe machine operations done either by holding the workpiece between centres or by a chuck:Turning Operation

between centres or by a chuck:Turning Operation

- Facing Operation

- Drilling

- Turning

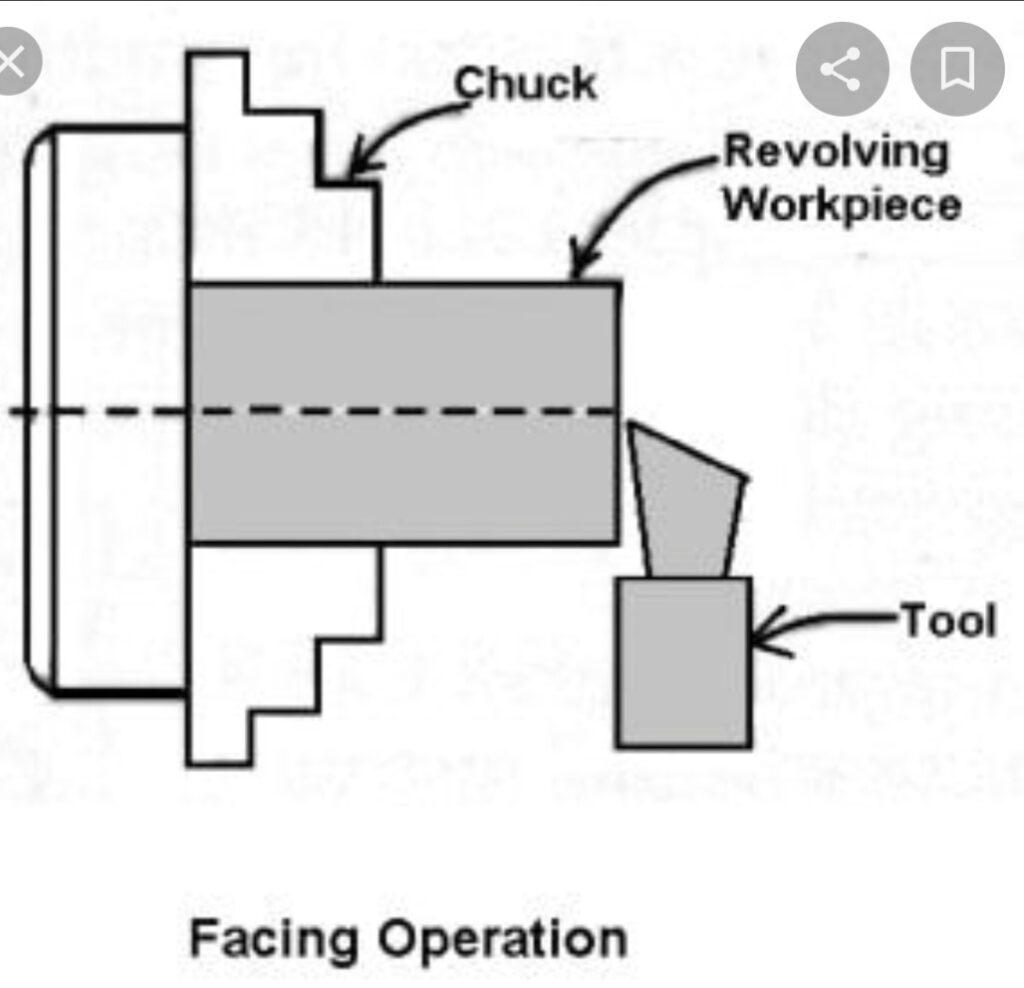

FACING

It is an operation of reducing the length of the workpiece by feeding the perpendicular to the lathe axis. This operation of reducing a flat surface on the end of the workpiece. For this operation, regular turning tool or facing tool may use. The cutting edge of the tool should set to the same height as the centre of the workpiece. Facing consist of 2 operations Roughing: Here the depth of cut is 1.3mm Finishing: Here the depth of cut is 0.2-0.1mm

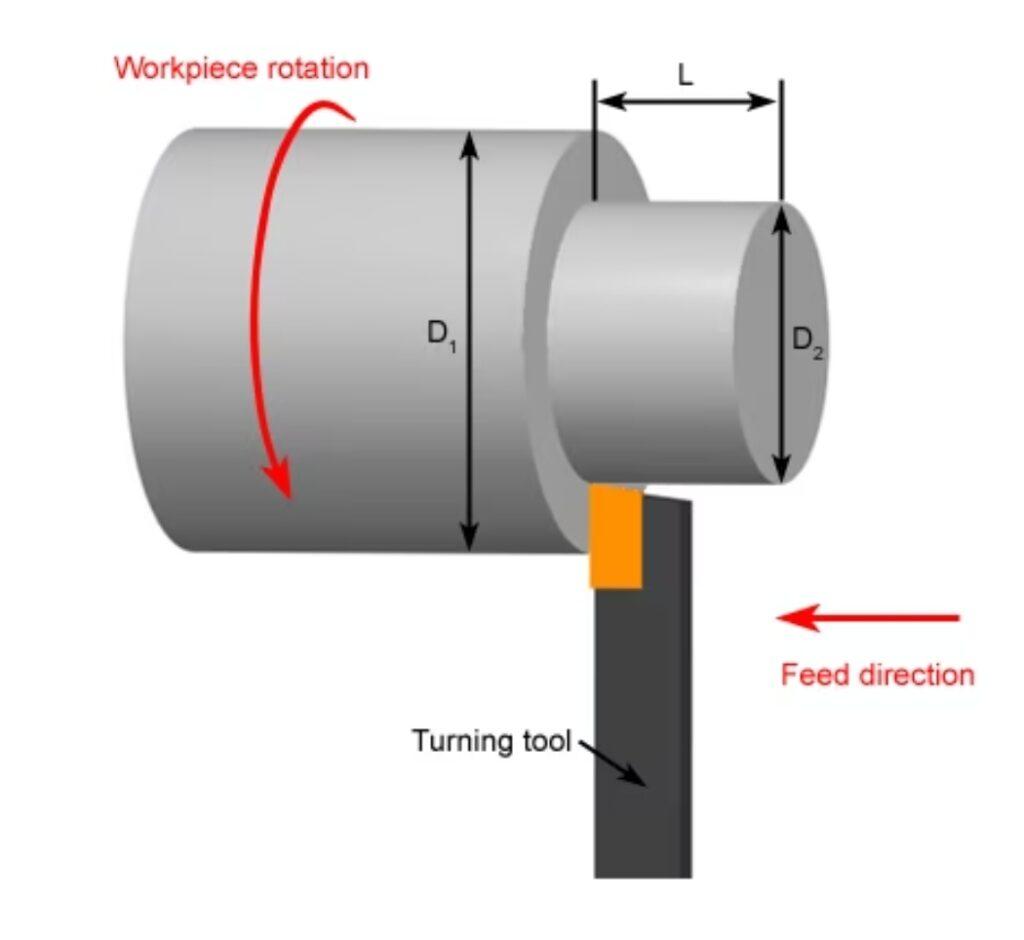

Turning:

It is the most common type of operation in all lathe machine operations.

Turning is the operation of removing the excess material from the

workpiece to produce a cylindrical surface to the desired length. The job

held between the centre or a chuck and rotating at a required speed. The

tool moves in a longitudinal direction to give the feed towards the

headstock with proper depth of cut. The surface finish is very good

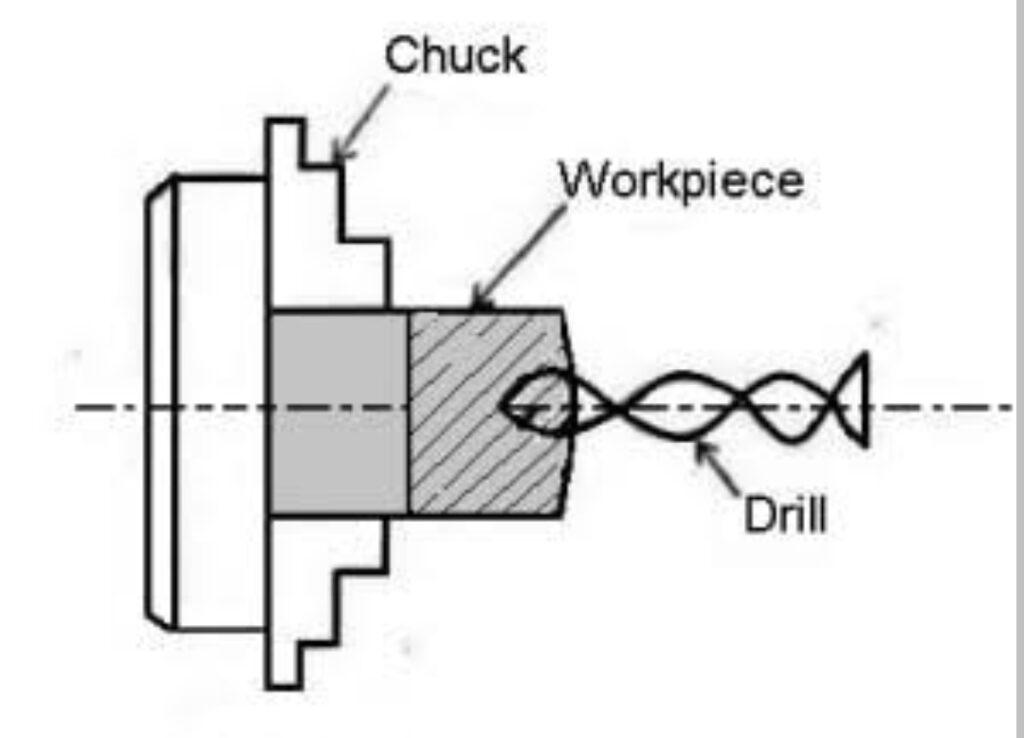

Drilling:

Drilling is the operation of producing a cylindrical hole in a workpiece. It is done by a

rotating tool, the rotating side of the cutter, known as a drilling drill. In this operation, The

workpiece is revolving in a chuck or a faceplate and the drill is held in the tailstock drill

holder or drill chuck The feeding is adopted is affected by the movement of the tailstock spindle. This method is adopted for the drilling of regular-shaped workpiece. Reaming: Reaming is the operation of finishing and sizing a hole which has

Really no matter if someone doesn’t be aware of then its up to other viewers that they will assist,

so here it takes place.セクシー ランジェリー

I visited various sites however the audio feature for audio songs existing at this website is in fact fabulous.

This is really interesting, I’ll check out your other posts!