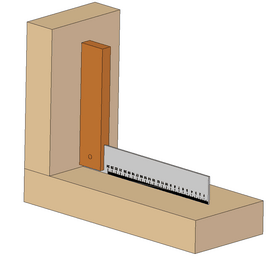

It is a hand tool checking squareness of the job.

It was manly two parts

1.Stock

2.Blade

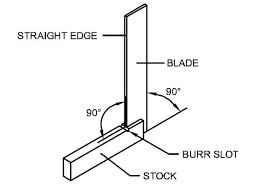

A try square consists of three main parts: the blade, stock, and handle. The blade, typically made of steel, forms the L-shaped edge used for measuring and marking right angles. Connected to the blade, the stock serves as the reference surface for ensuring squareness. It often features measurement markings for added precision. The handle provides a comfortable grip for control and stability during use. Together, these parts form a robust and reliable tool for woodworking and carpentry tasks. Whether in professional workshops or DIY settings, the try square’s components work in harmony to ensure accurate and perpendicular cuts and markings.

how many types of try square

3 types of try square

1.solid try square

2.Adjustable Try Square

3.Die Maker’s Try Square

Solid Try Square

In this type of try square, the blade is joined to the stock by a rivet at an angle of 90 degrees, so that the blade remains fixed in one place with the stock, hence it is also called a fixed try square. This type of tri square is used for simple tasks.A solid try square is a robust and reliable tool used in woodworking and carpentry. Constructed from a single piece of high-quality material such as steel or aluminum, it offers exceptional durability and stability. Its solid design ensures accuracy in measuring right angles and verifying squareness in projects. With a sturdy build and precise machining, it withstands heavy-duty use in professional workshops and construction sites. Solid try squares often feature ergonomic handles for comfortable grip and control during operation. Whether for marking, cutting, or checking squareness, the solid try square remains a trusted companion for craftsmen seeking accuracy and reliability in their work.

Adjustable Try Square

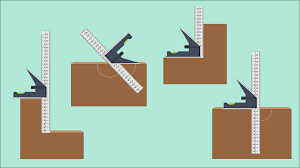

In this try square, the blade is not attached to the stock, but the stock can be adjusted using a knurled nut on the top of the blade. It is used where solid try square cannot be used. In this type of try Square, the angles on either side of the stock are right angles.

An adjustable try square is a versatile tool in woodworking and metalworking. Unlike traditional fixed-blade squares, it features a movable blade that can be locked at various angles, providing flexibility for diverse tasks. Commonly made with high-grade materials like stainless steel, it ensures durability and precise measurement. With adjustable blades, craftsmen can easily set desired angles for marking, cutting, or verifying squareness. This adaptability makes it invaluable for intricate projects where precise angles are crucial. Whether in professional workshops or DIY endeavors, the adjustable try square offers convenience and accuracy, enhancing the efficiency and quality of craftsmanship.

Die Maker’s Try Square

It is used to give different types of relief angles while making a die. Its stock has two screws at the bottom. A large screw is used to clamp the blade to a position with the stock. The Angle formed between the small screw blade and the stock can be set at a slightly greater or lesser angle than the right angle (90 °). Its set consists of four blades.

A die maker’s try square is a specialized precision tool essential in metalworking and machining. Specifically designed for the demanding requirements of die making, it features finely calibrated measurements and ultra-flat surfaces for utmost accuracy. Crafted from hardened steel or aluminum, it withstands rigorous use in industrial settings. Its compact size and ergonomic design facilitate precise layout and verification of angles in intricate die designs. With meticulous attention to detail, die maker’s try squares ensure the exactness necessary for creating molds and dies with tight tolerances. Trusted by professionals for their reliability and precision, they’re indispensable in precision engineering processes.

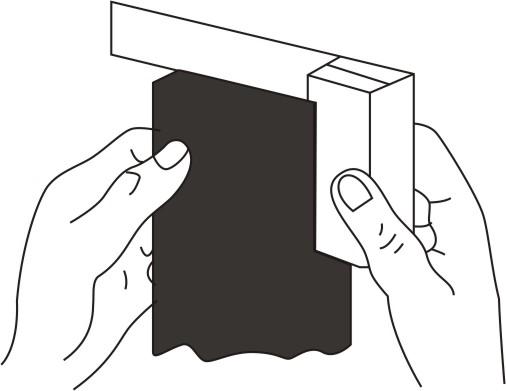

By Master Try Square

In this, the angle of 90 ° is measured by the master try square. If the light comes between the two blades when both are placed on the surface plate, then it is impure.

The Master Try Square, a woodworking essential, marries precision with simplicity. Crafted from steel, its L-shaped design ensures perpendicularity, aiding in accurate marking and cutting. The longer arm serves as a reliable edge for drawing straight lines, while the shorter one provides stability against surfaces. Its durability withstands the rigors of frequent use, maintaining accuracy over time. Whether crafting furniture or framing, this tool remains indispensable, embodying the craftsman’s commitment to excellence. From novice woodworkers to seasoned artisans, the Master Try Square stands as a symbol of meticulous craftsmanship, facilitating the transformation of raw materials into refined creations with exactitude.

The Master Try Square, a cornerstone of woodworking, blends precision and simplicity. Made of durable steel, its L-shaped design guarantees perpendicularity, aiding in precise marking and cutting. With a steadfast edge for straight lines and stability, it’s essential for craftsmen committed to accuracy in their creations.

Uses of Try Square

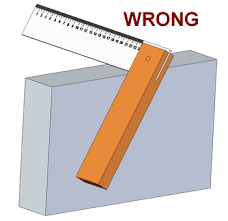

To check the flatness of the surface. To check the angle of 90 °.To draw parallel lines and to check them. To draw perpendicular lines on the edge of the job. To set the job at right angles.

The Try Square, a stalwart in woodworking, finds myriad uses beyond its namesake task. Its precision aids in marking and verifying right angles, crucial in joinery and cabinetmaking. Craftsmen rely on it to ensure accuracy when laying out cuts, guiding saws, or aligning components during assembly. Beyond woodworking, it serves in metalworking for layout and marking tasks. In construction, it verifies squareness in framing, ensuring structural integrity. Engineers utilize it in drafting and design for precise measurements. From hobbyists to professionals, the Try Square’s versatility and accuracy make it indispensable across various trades, embodying precision and craftsmanship.