Tolerance

Tolerance is described as the difference between the upper and lower limit. It is also defined as the difference between the maximum and minimum limits of size for the component. The tolerance is classified into two types:

- Unilateral tolerance

- Bilateral tolerance

Example: Hole has to be drilled to the diameter of 10±0.02 mm10±0.02 mm

Solution: The basic size of the hole is 10 mm and it is acceptable if its diameter lies between the limits of size.

The upper limit for the diameter of the hole is given as,

dmax=10 mm+0.02 mm

d max=10.02 mm

The lower limit for the diameter of the hole is given as,

d min=10 mm−0.02mm

d min=9.98 mm

The tolerance of the hole is given as,

d max−d mint=10.02 mm−9.98 m mt=0.04 mm

Thus, the tolerance of the hole is 0.04 mm.

Unilateral tolerance

Unilateral tolerance is described as the tolerance that allows variation in only one direction from the basic or nominal size. In unilateral tolerance, the size of the component is always either small or large from its basic size.

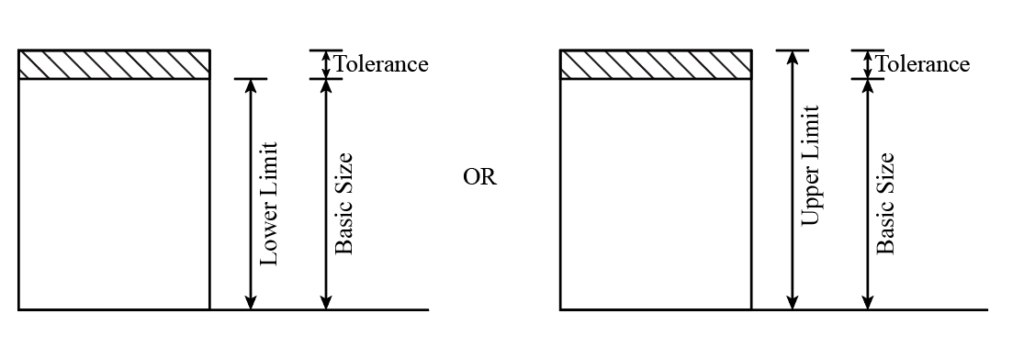

In unilateral tolerance, both upper and lower limits are either above or below the basic size of the component.

Example: 25+0.00+0.02 mm25+0.02+0.00 mm

The diagrammatical representation of the unilateral tolerance is shown as:

Bilateral tolerance

Bilateral tolerance is described as the tolerance that allows variation in both directions from the basic or nominal size. In unilateral tolerance, the size of the component may be small or large from its basic size. In bilateral tolerance, the maximum limit is above the basic size, and the minimum limit is below the basic size.

The combined plus or minus symbol is used with a single value to specify an equal variation in both directions.

Example: 25+0.02+0.02 mm25+0.02+0.02 mm