Hammer is a hand tool which is used to stick job or tool.It is used for forging, chipping, riveting, marking, nail hammering and removal and straightening cracked job .It design consisti of a pein at end , a face at the other end and an eye hole in the centre into which a handle is attached . Hammer are made from drop forged carbon steel, and its face and pein hard and temper

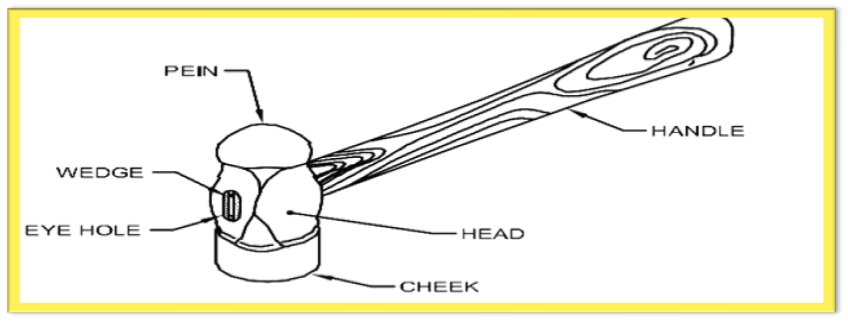

Main parts of hammer:-

1)Face 2)Check 3)Eye hole 4)wedge 5) handle 6) Peen

1.FACE:-It is the striking portion of the hammer it Is harden in nature.

2.CHECK:-It is soft in nature. It is observe the nitration during hammering.

3.Eye hole:- it gives path to thehandle for fitting.

4.Wedge:- it is the inside the eye hole it protest hammer flying Off .

6.HANDLE:- It is the wooden partsused for holding purpose.

5.Peen:-It is hardening surface opposite to the surface .it is used forming operation like bending see thing and riveting work.

An oval hole( eye hole or Elliptical hole ) is made in the part of the post( cheek)

- Handle is fitted in the middle of the elliptical hole or wedges is knocked in the middle

- Handle on average 250 cm Should be 325mm long

Handle length should be 200 to 260mm for light

hammer and 380 to 450mm for heavy hammer . - The weight of 500 gm hammer , handle length is 325mm.

- For normal work or marking work used the weight of 250gm ( ¼ kg or 0.25kg) hammer.

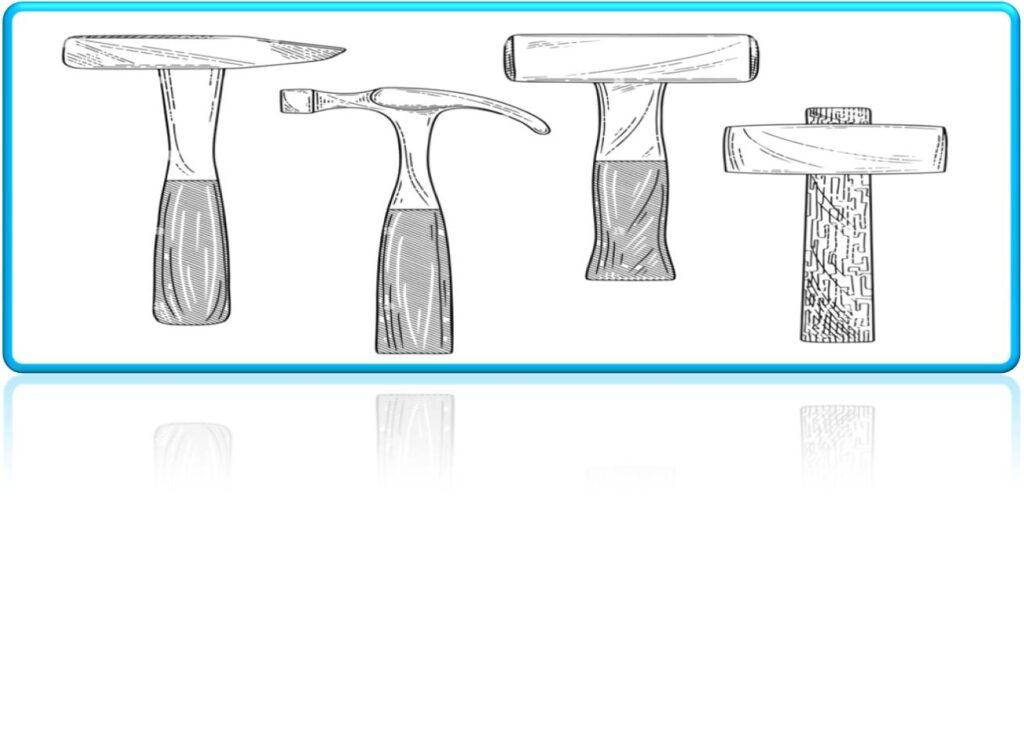

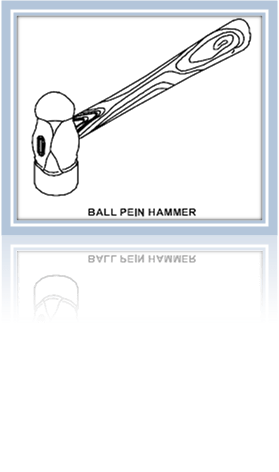

Ball peen hammer:-The shape of the peen of this type hammer is ball , it is used for chiseling and riveting .

Cross peen hammer :-The peen is parcel to the handle , it is used for bending & streting.

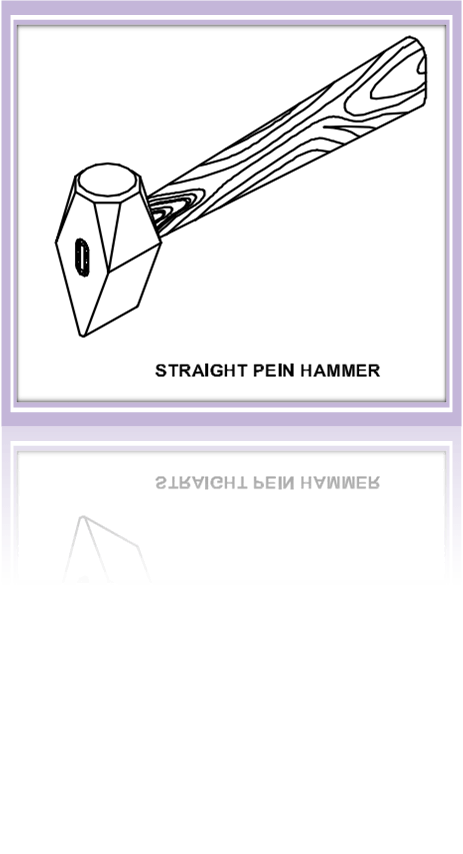

Straight peen hammer :-This hammer has a peen straight with the shaft i.e. parallel to the axis of the shaft. The is used for stretching or peening the metal.

Soft hammer :-Where it is necessary to strike metal a blow with the minimum damage to the surface , a soft hammer , called mallet .Its used for sifting job on the machine vice . It is prefect the surface from damage during hammering. These types of hammers are often made from soft metals like copper, brass, lead etc.

PRECAUTIONS

- Before working, it should be checked that there is nooil or grease on the face or handle of the hammer.

- The hammer should not be used without a wedge.

- Do not use hammers with broken handles or protruding faces.

- The hammer should be kept about 15 to 30 mm from the end of its handle while working. Should be caught.

- While hitting with a hammer, one should usually look at the place of injury and not towards the hammer.