Soldering and brazing are two commonly used techniques in various industries, including the field of Information Technology and Industrial Training Institute (ITI) programs. These processes are used for joining metal components together. Below, you will find detailed notes on soldering and brazing, including their definitions, equipment, techniques, and safety precautions.

Soldering:

Definition: Soldering is a process that involves joining two or more metal components together using a filler metal called solder. Solder typically has a lower melting point than the base metals, allowing it to flow and create a strong bond when heated.

Equipment:

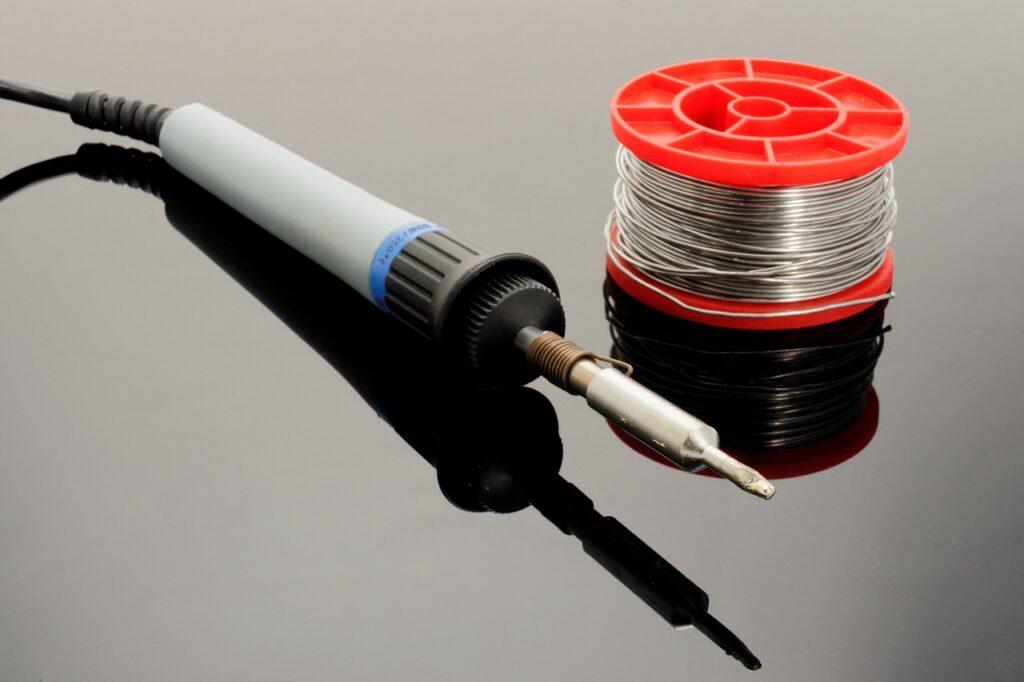

- Soldering Iron: A soldering iron is the primary tool used for soldering. It has a heated tip that melts the solder and applies it to the joint.

- Solder: Solder is a metal alloy typically composed of lead and tin, although lead-free alternatives are now widely used due to health concerns. Solder comes in various forms, such as wire or paste.

- Flux: Flux is a chemical compound applied to the joint to clean the metal surfaces and promote solder adhesion. It prevents oxidation and ensures a strong bond.

- Soldering Stand: A stand is used to hold the soldering iron when not in use to prevent accidents and damage to surfaces.

Soldering Techniques:

- Clean the Joint: Ensure that the metal surfaces to be soldered are clean and free from oxidation or contaminants. Use sandpaper or a wire brush if necessary.

- Apply Flux: Apply a small amount of flux to the joint to remove oxidation and enhance solder flow.

- Heat the Joint: Plug in the soldering iron and allow it to heat up. Touch the soldering iron’s tip to the joint to heat the metal.

- Apply Solder: Once the metal is hot enough, touch the solder wire to the joint, and it should melt and flow into the joint through capillary action. Avoid overheating.

- Remove the Soldering Iron: Once the joint is properly soldered, remove the soldering iron and allow the solder to cool and solidify.

Safety Precautions:

- Ventilation: Soldering can produce fumes, so work in a well-ventilated area or use a fume extractor to avoid inhaling harmful chemicals.

- Eye Protection: Wear safety glasses to protect your eyes from hot solder and flux splatter.

- Heat Protection: Use heat-resistant gloves to protect your hands from burns.

- Avoid Lead Exposure: If using lead-based solder, take precautions to avoid lead exposure, such as washing hands after handling solder and not eating or drinking while soldering.

Brazing:

Definition: Brazing is a process similar to soldering but uses a filler metal with a higher melting point. Brazing is employed when a stronger joint is required, and it is typically used for joining metals like steel, stainless steel, and copper.

Equipment:

- Brazing Torch: A brazing torch is used to heat the metal components and the filler metal to the appropriate temperature.

- Brazing Rods: Brazing rods, also known as filler rods, are made of alloys like brass, bronze, or silver. These rods melt at a higher temperature than solder.

- Flux: As in soldering, flux is used to clean the metal surfaces and aid in the brazing process.

Brazing Techniques:

- Clean the Joint: Clean the metal surfaces to be brazed thoroughly to remove any contaminants or oxides.

- Apply Flux: Apply flux to the joint to promote cleanliness and proper adhesion of the filler metal.

- Heat the Joint: Use the brazing torch to heat the metal components until they reach the melting point of the brazing rod. The filler metal will flow into the joint, creating a strong bond.

- Cool the Joint: Allow the brazed joint to cool slowly to avoid stress cracks.

Safety Precautions:

- Protective Gear: Wear appropriate protective gear, including heat-resistant gloves, safety glasses, and a welding apron.

- Ventilation: Work in a well-ventilated area or use a fume extractor to remove any fumes generated during brazing.

- Fire Safety: Be mindful of fire hazards, as brazing involves high temperatures. Have a fire extinguisher nearby and keep flammable materials away from the workspace.

- Proper Training: Ensure that individuals performing brazing are adequately trained in the technique to minimize accidents.

Both soldering and brazing are valuable skills in various industries, and ITI students can benefit from learning and mastering these techniques as they are commonly used in electronic assembly, plumbing, HVAC, and metalworking applications. Following safety guidelines is crucial to prevent accidents and ensure successful soldering and brazing operations.