- Introduction :- A screw is a small metal rod with a notch in the top that’s used as a fastener. You can attach one piece of wood to another by rotating a screw through the two surfaces.

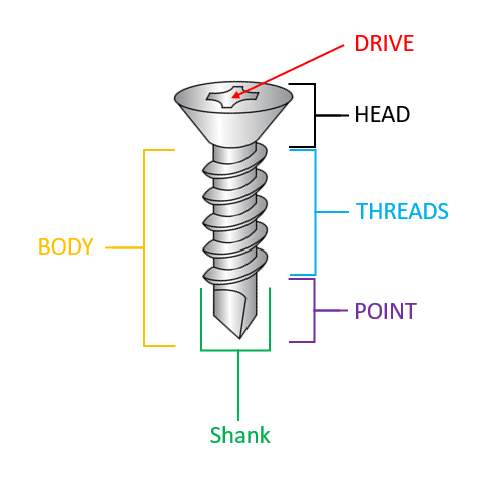

- Parts of screw:-

- Types of screw :-

1. Wood Screws: Wood screws are designed for use in wood materials. They have a coarse thread and a sharp point, making them suitable for gripping wood fibers and holding things together securely. These screws often come with various head types, such as flat head, round head, and pan head.

2. Machine Screws: Machine screws are used in metal or other rigid materials. They have a finer thread and are typically used with nuts or threaded holes. Machine screws come with a variety of drive types, such as slotted, Phillips, or hex.

3. Sheet Metal Screws: Sheet metal screws, also known as self-tapping screws, are designed for use in thin metal sheets or plastic materials. They have a sharp, self-tapping thread that creates its mating threads as it is driven into the material.

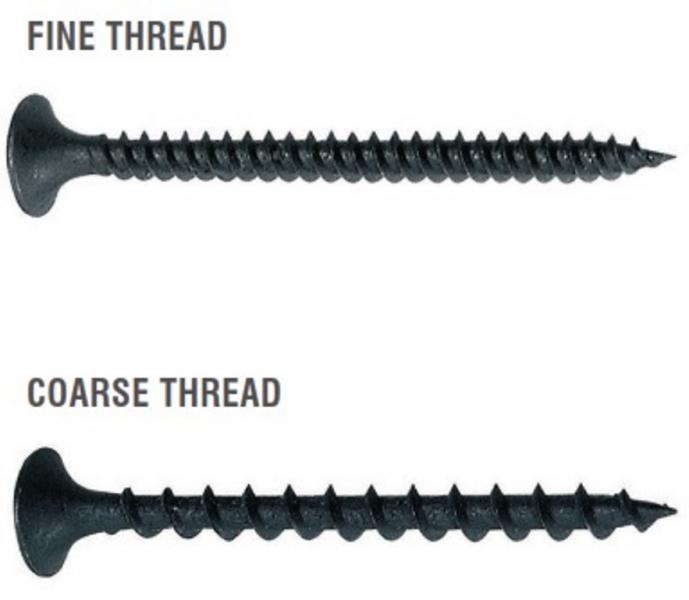

ACCORDING TO THREAD

1.Coarse Thread Screws: Coarse thread screws have widely spaced threads, which means fewer threads per inch of length. They are commonly used in soft materials like wood and plastics. The larger gaps between threads allow for quicker insertion and provide better holding power in softer materials.

2.Fine Thread Screws: Fine thread screws have tightly spaced threads, with more threads per inch of length. They are commonly used in metal and harder materials. The increased number of threads provides better holding power in denser materials and offers greater resistance to vibrations.

3.Self-Tapping Screws: Self-tapping screws have a special type of threading that allows them to create their own threads in the material as they are driven in. They are often used in materials like metal, plastic, and wood.

4.Machine Screws: Machine screws typically have a uniform thread along the entire length of the screw. They are used in metal parts and components with pre-threaded holes or with nuts to fasten components together.

5. Thread-Cutting Screws: Thread-cutting screws have a unique threading profile with a gap followed by a cutting edge. They are designed to cut mating threads into the material they are driven into, usually used with metal or plastic.

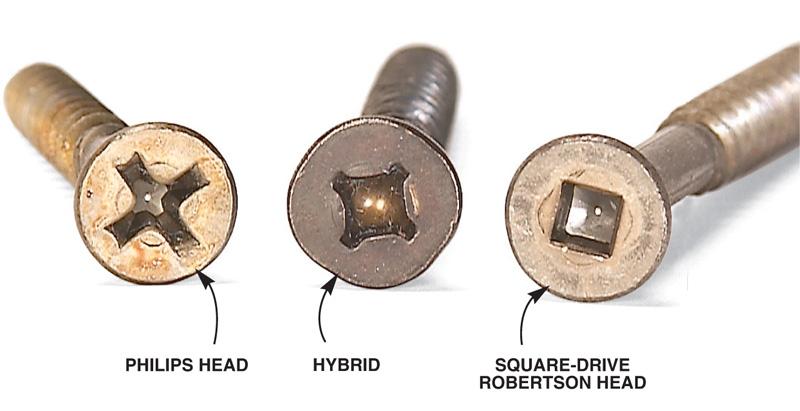

ACCORDING TO HEAD

1. Flat/Slotted Head: This is one of the oldest and most traditional screw head types. It has a single slot in the head, which requires a flat-bladed screwdriver (also known as a slotted or flat-head screwdriver). While it’s widely used, it can be challenging to use because the screwdriver tends to slip out of the slot easily.

2. Phillips Head: The Phillips head is another prevalent screw head type. It has a cross-shaped indentation in the head and requires a Phillips screwdriver. This design is intended to provide better torque and reduce slippage compared to the flat head. Phillips screws are widely used in many applications, from household items to industrial machinery.

3. Hex/Allen Head: Hex or Allen head screws have a hexagonal socket in their heads, requiring an Allen wrench (also known as a hex key) to drive them. These screws are commonly used in furniture assembly, machinery, and other applications where a flush surface is desired.

4. Trox HeadTrax screws have a six-pointed star-shaped socket in their heads, and they require a corresponding Torx screwdriver or bit. The design offers higher torque transfer and reduces the likelihood of cam-out (slippage) during installation. Torx screws are often used in automotive, electronics, and other high-torque applications.

5. Phillips Square-Drive Head (Robertson Head): The Phillips Square-Drive, also known as the Robertson head, combines features of the Phillips and square-drive screw heads. It has a square-shaped socket with a cross-shaped recess inside. This design provides better torque transfer and helps prevent slippage. The Robertson head is commonly used in construction and woodworking industries.

Materials:-

1.Steel:Steel screws are the most widely used and come in different grades, such as carbon steel and stainless steel. Carbon steel screws are strong and economical but are susceptible to rust and corrosion. Stainless steel screws, on the other hand, are more resistant to rust and corrosion, making them suitable for outdoor and marine applications.

2.Brass: Brass screws are corrosion-resistant and have good electrical conductivity. They are commonly used in applications where aesthetics are essential, such as in furniture and musical instruments.

3.Aluminum: Aluminum screws are lightweight and corrosion-resistant, making them suitable for applications where weight is a concern or in environments where corrosion is a potential issue.

4.Plastics: Screws made from various plastics, such as nylon or polyethylene, are commonly used in applications where electrical insulation, chemical resistance, or lightweight properties are required. They are also used in industries like electronics and automotive.

5.Bronze: Bronze screws are used in marine and outdoor applications due to their corrosion resistance and durability.

6.Copper: Copper screws are primarily used in electrical applications because of their excellent electrical conductivity.

7.Zinc: Zinc-coated screws provide some level of corrosion resistance and are often used in indoor applications.

USES OF SCREW

1.Construction and Woodworking: Screws are widely used in construction and woodworking projects. They are used to fasten materials like wood, metal, and plastic. Whether it’s building furniture, cabinets, or installing drywall, screws provide a secure and durable connection.

2.Electronics and Appliances: Screws are essential in the manufacturing and repair of electronics and appliances. They are used to hold components, circuit boards, and casings together. In electronics, small screws are often used to secure the back panels of smartphones, laptops, and other gadgets.

3. Automotive Industry: The automotive industry relies heavily on screws for assembling various components of vehicles. Screws are used in engine parts, interior panels, chassis components, and even in the assembly of electronic modules.

4.Medical Implants: In the medical field, screws are used as essential components of implants for orthopedic surgeries. They are used to fixate bones and joints during procedures like spinal fusions and fracture repairs.

5.Industrial Machinery and Equipment: Screws play a vital role in assembling and maintaining industrial machinery and equipment. They are used in conveyor systems, manufacturing equipment, and other industrial applications to hold components together securely.