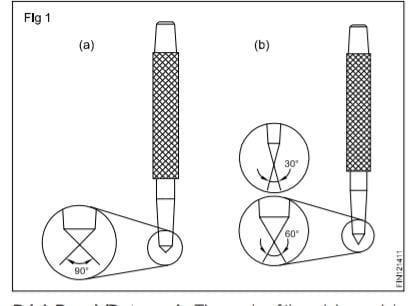

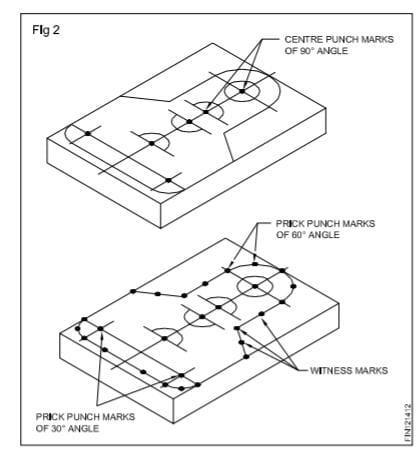

Punches are used in order to make certain dimensional features of the layout permanent. There are two types of punches. They are centre punch and prick punch made of high carbon steel, hardened and ground. Centre Punch: The angle of the point is 90° in a centre punch.

The punch mark made by this is wide and not very deep. This punch is used for locating centre of the holes. The wide punch mark gives a good seating for starting the drill. (Fig 1a) Prick Punch/Dot punch.

The angle of the prick punch is 30° or 60°. The 30° point punch is used for making light punch marks needed to position dividers. The divider point will get a proper seating in the punch mark. The 60° punch is used for marking witness marks .

Type of Punch

1–Dot Punch

2–Centre Punch

3–Prick punch

4–pin punch

5–Drift Punch

6–Bell punch

7–Automatic centre punch

8–Hollow punch

9–Solid punch

The centre punch is made form mild steel with the point hardened and tempered so that it withstands impact with the material it is marking. … The dot punch is a lighter and thinner version of the centre punch and is used basically for the same job. However, it is more accurately as the dot produced is smaller.

Dot punch– It is moulded of cast steel and it’s pointer has 60degree.

Prick Punch — is similar to a center punch but used for marking out. It has a sharper angled tip to produce a narrower and deeper indentation. The indentation can then be enlarged with a center.

Pin Punch –

: a punch used to dislodge rivets and pins.

Drift Punch—– Drift punch or drift pin, or lineup punch, is used as an aid in aligning bolt or rivet holes prior to inserting a fastener. … The long end of a drift punch is placed into the semi-aligned bolt holes of two separate components, and then driven into the hole.

Bell punch–The Bell Punch Company was a British company manufacturing a variety of business machines, most notably several generations of public transport ticket machines and the world’s first desktop electronic calculator, the some luck

What is an automatic center punch used for?

An automatic center punch is a hand tool used to produce a dimple in a workpiece (for example, a piece of metal). It performs the same function as an ordinary center punch but without the need for a hammer.

Hollow (leather) Punches- Excellent tool to punch Accurate Hole in gasket Material, light gauge sheet metal, Vinyl, Plastic, Leather, and more. – Made from hardened & tempered high Carbon Steel. – Precision Ground edges facilitates easy cutting. – Inside taper for clearance.

Solid punches are one-piece rod-shaped tools made of metal designed to be struck by a hammer. They are typically used to drive objects such as pins or to form impressions on a work piece. Solid punches can vary in diameter, length and tip depending on the job to be perfect.

It is used to tightly fit the tolerances of an existing hole and, when struck, precisely transfer the center of that hole to another surface.

What is punch process?

Punching is a machining process that involves the removal of scrap metal from a sheet of raw metal. It requires the use of a punch press to compress a tool through a sheet of raw metal. While punching is typically performed using sheet metal, it supports other materials like paper, plastic and various fibers.

A punch is a hard metal rod with a shaped tip at one end and a blunt butt end at the other, which is usually struck by a hammer to form an impression of the tip on a workpiece. Punches are usually classified according to the shape of their points.

Thanks for your blog, nice to read. Do not stop.