A drill is a tool that uses rotation or a chipping motion to make a hole.

What is the Drilling Process ?

We can also explain as Drilling is an operation of making a circular hole by removing a volume of metal from the job by cutting tool called drill. A drill is a rotary end-cutting tool with one or more cutting lips and usually one or more flutes for the passage of chips and the admission of cutting fluid.

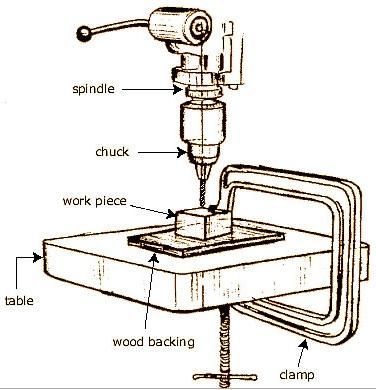

The most common machining operations performed on a drill press are follows

Drilling

Reaming

Counterboring

Countersinking

Spot Facing.

What is .........

Drilling is a cutting process that uses a drill bit to cut a hole of circular cross-section in solid materials.

Reaming is a sizing operation that removes a small amount of metal from a hole already drilled. It is done for two purposes: to bring holes to a more exact size and to improve the finish of an existing hole.

Counterboring is a method used to create an even surface on the inside wall of a pipe end.

Countersinking is a process that creates a V-shaped edge near the surface of a hole. It is often used to deburr a drilled or tapped hole, or to allow the head of a countersunk-head screw to sit flush or below a surface

The most common application of spot facing (spot facing) is facing the area around a bolt hole where the bolt’s head will sit, which is often done by cutting a shallow counterbore, just deep enough “to clean up”—that is, only enough material is removed to get down past any irregularity and thus make the surface flat.

VIDEO CLASS

SUGGESTED VIDEOS

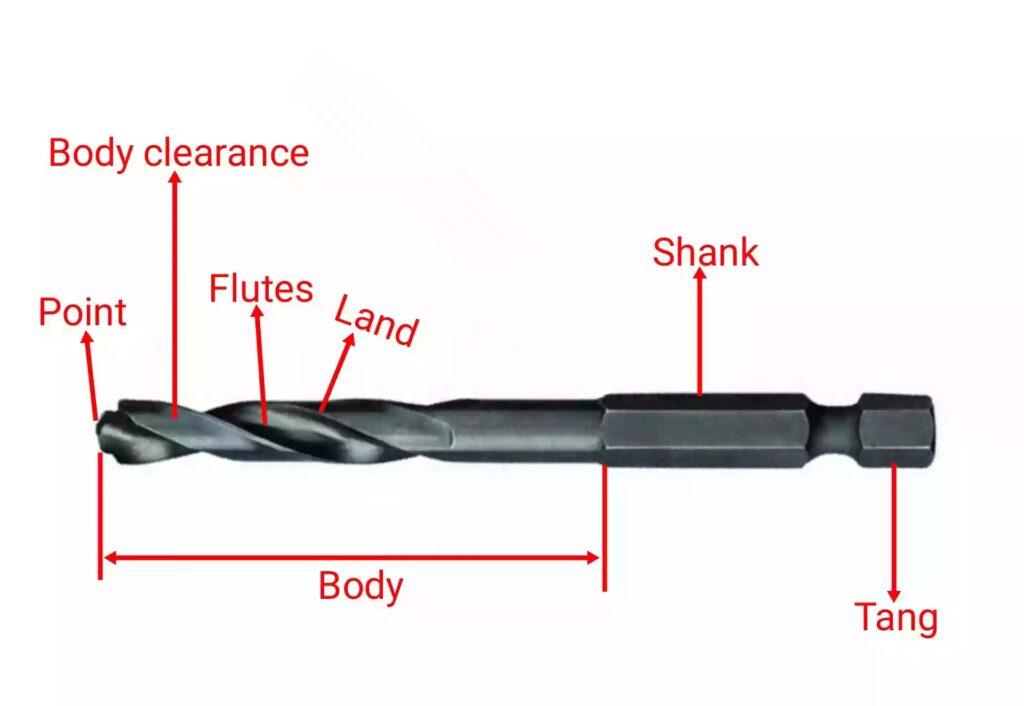

Parts of a Drill Bit

Body

Shank

Tang

Cutting Point

Flute

Land