Introduction

´It is a tool having a cutting point and making a hole in the solid materials.

´It is made up of high carbon steel or alloy steel.

´For drilling, the drill bit is rotated with a downward press, which causes the tool to penetrate into the material.

´It is also called a drill.

´For holding the drill bit a work holding device is used which is known as a drill chuck in a drilling machine.

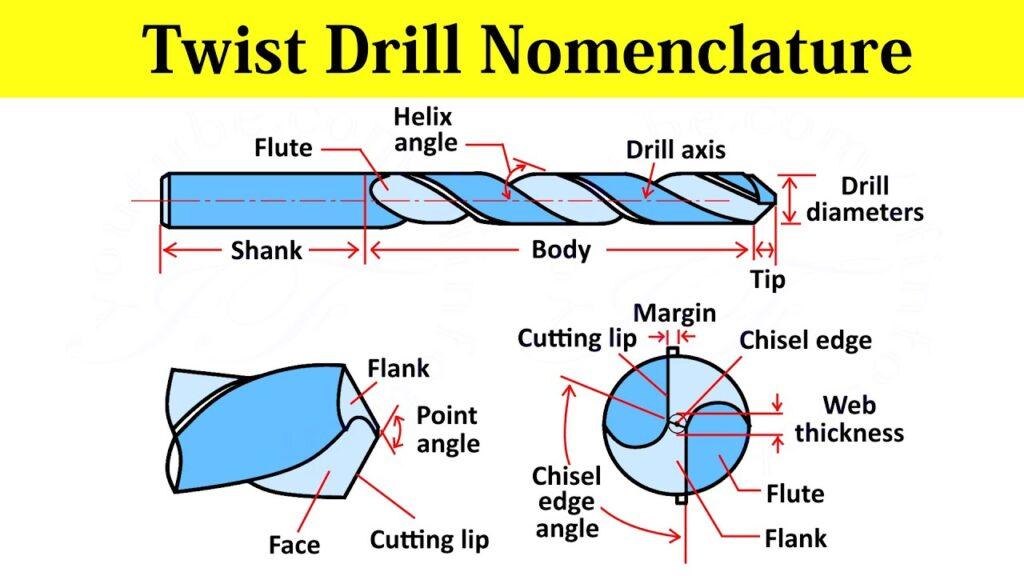

DRILL BIT AND PARTS

•Body

•The body between the shank and the point of the drill is called the body.

•Point

•The end point of the drill is called point and it is cone shaped.

•It is generally found at 180°.

•Shank

•The driving end of the drill which fits into the drilling machine is called a Shank.

•Tang

•Tang is a part of the shank that fits into the machine spindle.

•Flutes

•Spiral grooves on the body of the drill are called flutes.

•They mainly do three types of tasks: first, metal cutting as cutting edge, and secondly

•Turning out the chips into curls and the third, coolant reaching the cutting edge.

•Land

•The length of the body across the body between the flutes says land.

•It’s also known as a margin.

•Body Clearance

•The part of the body whose diameter is slightly less than the diameter of the drill is called body clearance.

•Due to this, the friction between the drill and the hole is reduced.

•Web

•The part separating the two flutes is called the web.

TYPES OF DRILL BIT

1.Flat Drill Bit

2.Fluted Drill Bit

3.Taper Shank Drill Bit

4.Oil hole drill Bit

5.Centre Drill Bit

6.Counter Bore Drill Bit

7.Multi-diameter Drill Bit

8.Counter Sink Drill Bit

TYPES OF DRILL BIT PARTS DESCRIPTION

•Fluted Drill Bit

•Flutes are made in the body of such a drill bit.

•Types of fluted Drill bit

•The fluted drill bit can be divided into two types which are following:

1.Straight Fluted Drill Bit

2.Twist Drill Bit

•chips to exit from the hole.

1.Multi Flutes Drill Bit

•Types of Twist Drill Bit

•There are two types of twist drill such as:

1.Two Flutes Drill Bit

2.Multi Flutes Drill Bit

•Two Flutes Drill Bit

•It is rigid and does not use deep holes.

•Multi Flutes Drill Bit

•It is used for drilling deep holes because there is a maximum space for chips to exit from the hole.

Center Drill Bit

It is used for drilling a conical shape on both ends of a job or workpiece at the lathe machine or the milling machine.

Counter Bore Drill Bit

It is used for drilling and boring operation

Multi-diameter Drill Bit

It has the property to make the different diameters of a hole at a time.

It has drilled the taper and straight shank.

It is used in step drilling so it is also called a step drill.

Counter Sink Drill Bit

It is used to change the shape of a hole.

It has a show length of a body with flutes.

Its cutting point grinded from 60° to 82° angle

MATERIAL

The materials for the manufacturing of drills are as follows:

1. – high-speed steel.

2. – Carbon steel

USES

IT IS USE MOSTLY TO MAKING A HOLE IN THE WORK PIECE

IT SHOULD BE CIRCULAR & CYLINDRICALL