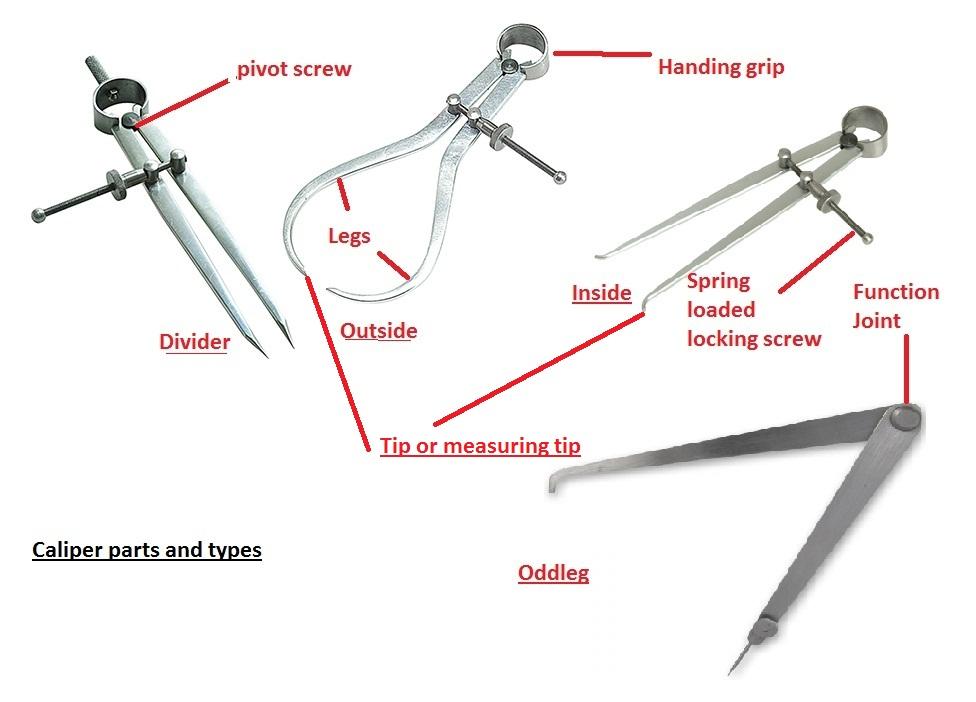

It is a device use to transfer & compare dimension form one object to another or from a part to scale. A caliper as simple as a compass with inward & outward facing point. The tips of the caliper adjust to fit across the points to be measured the caliper the removed the distance read by measuring between the tips with a measuring tool , such as steel rule.

How many type of caliper

1. Outside caliper 3. Divider caliper

2. Inside caliper 4. Odd leg caliper

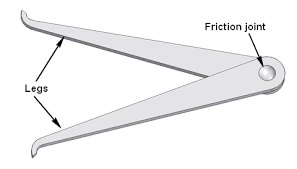

(1)OUTSIDE CALIPER

An outside caliper is two tagged steel instrument its legs bent in ward. A Steel rule must be used in Conjunction with than direct reading deseeds. These are specially use full when measuring very large distance, large diameter pipe. A venire does not have the depth capacity there large diameter while at the same depth the outer most points of the pipe’s diameter.

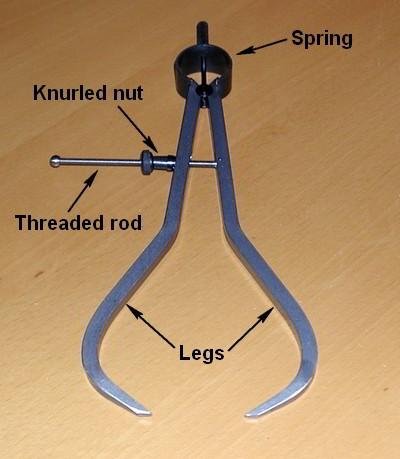

(2)INSIDE CALIPER

An inside caliper is exactly similar to outside caliper in appearance. But its leg bent out word. It is used for comparing or measuring hole diameter, distance between the shoulders. For getting specify reading Steel rule must be used. The upper one is manually adjusted. The lower one adjusting screw. It to carefully adjust without removal of the tool form the work pieces .

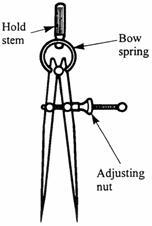

(3)Divider caliper

A divider is similar in construction to a caliper expect that both legs are straight with sharp hardened points at the end . In the metal working field Divider caliper is used in the press of making out suitable work piece. The two caliper ends are brought to the two points whose distance is being measured. The caliper opening is then either measured one separate ruler, the converted to the actually distance

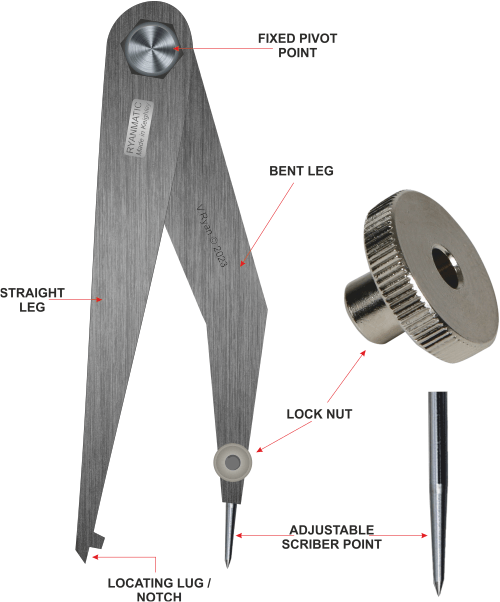

(4)ODD LEG CALIPER

This are also called hermaphrodite caliper or odd leg caliper & jenny caliper is used to scribe a line set distance from the edge of the work Piece. The bent leg is used to run along the working edge while the scriber makes it mark at a determined distance. The ensure a line parallel to the edge. The upper most calipers has a slight shoulder in the bent leg allowing it to sit more securely on the edge.

The Safety of CALIPER

Welcome to our presentation on the safety of CALIPER. Discover how our innovative technology prioritizes safety in the laboratory environment. Prioritizing safety ensures the well-being of laboratory professionals, reducing the risk of accidents or injuries during CALIPER operations. Guaranteeing safety in CALIPER usage ensures that samples remain uncontaminated, providing accurate results and reliable data. Following safety protocols prevents damage to the CALIPER instrument, prolonging its lifespan and optimizing functionality.

Conclusion

Recap of CALIPER Safety Measures

We discussed the importance of risk analysis, emergency shutdown procedures, safety training, and protective equipment usage. Operators receive dedicated safety training, equipping them with the knowledge and skills to handle CALIPER safely. Prior to usage, CALIPER undergoes rigorous risk analysis to identify potential hazards and implement safety measures accordingly. CALIPER features an emergency shutdown protocol, ensuring swift and effective cessation of operations in hazardous situations.

Importance of Prioritizing Safety

Remember, safety is paramount when using CALIPER. It ensures a secure environment for laboratory professionals and reliable data outcomes. Proper personal protective equipment, such as gloves and goggles, must be worn by operators to minimize potential risks. Ensuring clutter-free workspaces reduces the chances of accidents and helps maintain a safe environment during CALIPER usage. Routine equipment maintenance protocols are vital to detect and address any safety concerns or instrument malfunctions.