Precision Measuring for Machinists. The sine bar is an essential tool for machinists to ensure precision measurements. Discover its parts, materials, uses, safety measures, and tips for accurate readings with this comprehensive guide

Sine Bar: Precision Measuring for Machinists

The sine bar is an essential tool for machinists to ensure precision measurements. Discover its parts, materials, uses, safety measures, and tips for accurate readings with this comprehensive guide.

by ASHISH TAKRI

Introduction to Sine Bar

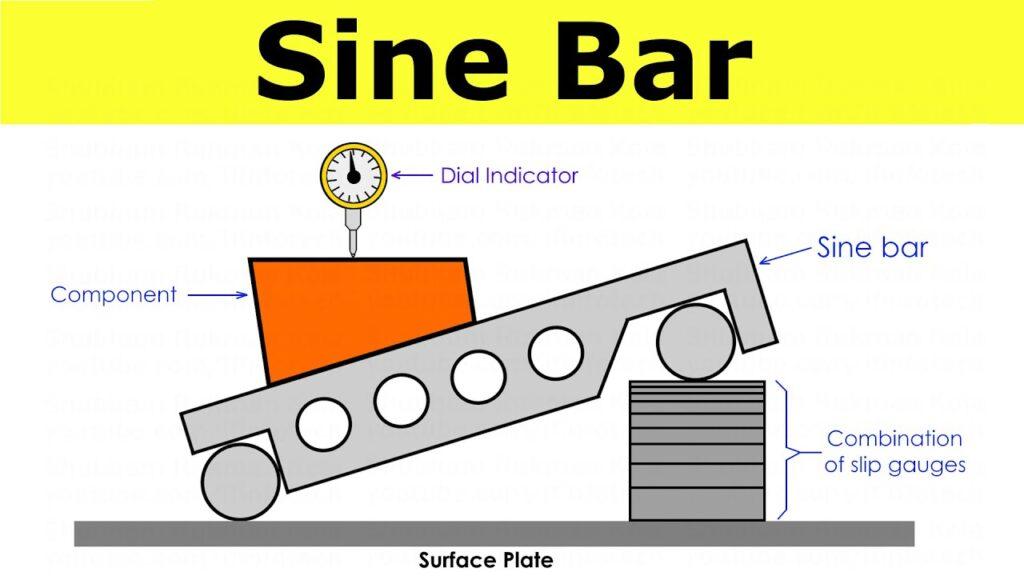

What is a Sine Bar?

A measuring instrument used for precise angle measurement in metalworking.

Why is it essential?

It ensures precise measurement, saving time and money by minimizing mistakes and rework.

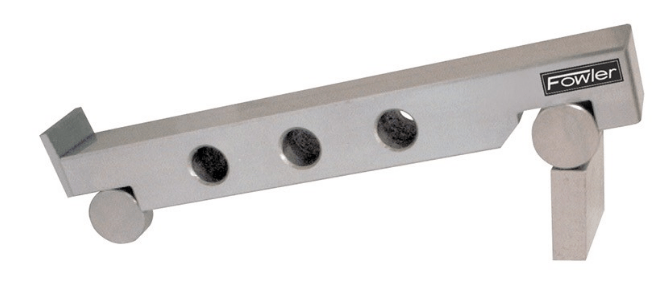

Parts of a Sine Bar

Base

Used as a reference surface, and connected to the other components.

Block

Has a precise angle that is set with gauge blocks.

Clamps

Used to hold the gauge blocks securely in place.

Materials Used in Sine Bars

Applications and Uses of Sine Bars

Machining Processes

Used to set up milling machines, grinding machines, and other metal cutting tools.

Safety Measures When Handling Sine Bars

Only use sine bars if you have proper training and experience. Ensure the surface plate is clean and flat.

Wear safety glasses and protective gloves when handling sine bars.

Conclusion and Summary

The sine bar is a vital tool for machinists, providing precision measurement, flexibility, and versatility. By understanding its components, uses, and safety measures, machinists can enhance their efficiency, accuracy, and quality.

Sine Bar: Precision Measuring for Machinists

The sine bar is an essential tool for machinists to ensure precision measurements. Discover its parts, materials, uses, safety measures, and tips for accurate readings with this comprehensive guide.

by ASHISH TAKRI

Introduction to Sine Bar

What is a Sine Bar?

A measuring instrument used for precise angle measurement in metalworking.

How does it work?

By placing it on a surface plate, and using it to set an adjustable angle gauge block at a desired angle.

Why is it essential?

It ensures precise measurement, saving time and money by minimizing mistakes and rework.

Parts of a Sine Bar

Base

Used as a reference surface, and connected to the other components.

Block

Has a precise angle that is set with gauge blocks.

Clamps

Used to hold the gauge blocks securely in place.

Materials Used in Sine Bars

Applications and Uses of Sine Bars

Machining Processes

Used to set up milling machines, grinding machines, and other metal cutting tools.

Gauging

Used to verify the accuracy of gauges and measurement tools. Example: Setting a sine gauge on inspection equipment.

Measurement

Used to measure angles precisely. Example: Virtually any angle found on a print drawing.

Safety Measures When Handling Sine Bars

Only use sine bars if you have proper training and experience. Ensure the surface plate is clean and flat.

Wear safety glasses and protective gloves when handling sine bars.

Conclusion and Summary

The sine bar is a vital tool for machinists, providing precision measurement, flexibility, and versatility. By understanding its components, uses, and safety measures, machinists can enhance their efficiency, accuracy, and quality.